History of Cassette Tapes Part 3: Magnetic Recording Fundamentals

Share

Introduction

The journey of magnetic tape recording provides a fascinating glimpse into how electromagnetic principles revolutionized audio storage. This transformation from mechanical systems to magnetic tapes marked a significant milestone in the evolution of sound recording technologies.

In this article we will delve into the basic physical and technological aspects of how magnetic recording and playback work. The subject is not trivial, but we will try to make it accessible even for those with no previous knowledge, and to do that we must start with the basic terminology and definitions. These will be necessary as we continue to explore the magic of cassette tapes in depth.

At the end of the article, you will find links to the source of the images which contain additional information about each topic.

Foundations

Electromagnetic Fields

An electromagnetic field (EM field) is a physical field, mathematical functions of position and time, representing the influences on and due to electric charges. The field at any point in space and time can be regarded as a combination of an electric field and a magnetic field which are perpendicular to each other. Because of the interrelationship between the fields, a disturbance in the electric field can create a disturbance in the magnetic field which in turn affects the electric field, leading to an oscillation that propagates through space, known as an electromagnetic wave.

In magnetic recording, the magnetic component of the electromagnetic field aligns the magnetic particles on the tape to store audio signals.

Figure 1 - Electromagnetic Fields in a Plasma Globe

Magnetic Flux

Magnetic flux refers to the quantity of magnetism, considering the strength and extent of a magnetic field, measured in Weber (Wb), is a measure of the total magnetic field which passes through a given surface. The magnetic flux through a surface depends on the area of the surface, the strength of the magnetic field the surface is in, and the angle between the surface and the magnetic field.

Figure 2- Magnetic Flux

The amount of magnetic flux affects how strongly the magnetic particles on the tape are aligned.

Magnetic Domains

A magnetic domain is a region within a magnetic material in which the magnetization is in a uniform direction. This means that the individual magnetic moments, the combination of strength and orientation of a magnet or other object or system that exerts a magnetic field, of the atoms are aligned with one another, and they all point in the same direction.

Figure 3 - Magnetic Domains

Altering the alignment of these magnetic domains of the ferromagnetic material on the tape, using an external magnetic field created by the recording head, is the fundamental process behind magnetic audio recording.

Coercivity

Coercivity measures a material's resistance to changes in magnetization. Specifically, it is a measure of the ability of a ferromagnetic material to withstand an external magnetic field without becoming demagnetized.

Ferromagnetic materials with high coercivity are called magnetically hard and are used to make permanent magnets. Materials with low coercivity are said to be magnetically soft. The latter are used in transformer and inductor cores, recording heads, microwave devices, and magnetic shielding.

Figure 4 - Coercivity

Materials with high coercivity retain their magnetization better, which is crucial for ensuring the longevity and stability of recorded audio. On the other hand, recording heads must have low coercivity.

Permeability

Magnetic Permeability is a value that expresses how a magnetic material responds to an applied magnetic field. If a material's internal dipoles become easily oriented to an applied magnetic field, that material is regarded as being a high-permeability material. If the material's internal dipoles do not become easily oriented to an applied magnetic field, it is a low-permeability magnetic material.

Figure 5 - Permeability

Hard magnetic materials like iron oxide, gamma ferric oxide, and chromium dioxide are often used in recording tape and other media. Soft magnetic materials like Alfesil, hot-pressed ferrite, and Permalloy have higher permeability and are used to make magnetic head cores.

Electromagnetic Induction

Discovered by Michael Faraday in 1831, this principle is the basis for magnetic recording. It refers to the process by which a changing magnetic field induces an electric current in a conductor. This principle is harnessed in recording technology to convert audio signals into magnetic fields and vice versa.

Figure 6 - Electromagnetic Induction

Saturation

In magnetic recording, saturation occurs when all magnetic domains within the tape material are fully aligned with the applied magnetic field. Beyond this point, no further increase in magnetization is possible.

Figure 7 - Saturation

Understanding saturation is crucial for knowing the limitations and capabilities of recording media.

Remanence and Retentivity

These terms describe the residual magnetism left in a material after the external magnetic field is removed. High remanence in a tape means the tape can hold a strong magnetic signal (audio information) for a long time, making it an essential property for recording media.

Putting It All Together…

Magnetic recording operates on the basic principle of electromagnetic induction, where electric currents and magnetic fields interact. This interaction is the backbone of the recording process. Magnetic fields are generated by electric currents passing through coils in the recording heads, which then alter the magnetic orientation of particles on the tape. The alignment of these particles forms a magnetic pattern that replicates the original audio signal. Understanding this process is essential for appreciating the technical achievements and challenges of magnetic tape technology.

Furthermore, magnetic tape recording involves intricate mechanics and material science, including the manipulation of magnetic flux and domain alignment in the recording medium. These processes rely on precise control of the electromagnetic properties of the materials used, highlighting the complex interplay between physics and engineering in audio technology. This introduction sets the stage for a deeper exploration of the materials and mechanisms that define magnetic tape recording. We will continue to use these terms in the following articles when we reveal more of the intricacies that can help you make the most of your cassette tapes.

Heads up!

Record, playback, and erase heads are the critical components in the magnetic recording process. They convert the electrical analog music signals into magnetic fields and vice versa, playing a pivotal role in the quality of audio reproduction. Understanding the materials and construction of these heads is essential to appreciate how they function and impact the performance of magnetic tapes. They are constructed from sophisticated materials such as ferrite, permalloy, and Sendust, each type of head offers specific benefits that impact sound quality and durability.

Figure 8 - Tape Head

Head Materials

Recording heads are typically made from high-permeability materials, which are crucial for efficiently transmitting and receiving magnetic fields. The most common materials used for head construction include ferrite, permalloy, sendust, and amorphous each offering distinct advantages and trade-offs.

Ferrite is a ceramic material with magnetic properties, is widely used in recording heads due to its durability and resistance to wear. Ferrite heads are particularly suitable for high-use applications where longevity is a priority. However, ferrite can be brittle, which requires careful handling and precise manufacturing to avoid damage during production and use.

Permalloy Heads are made of an alloy composed mainly of nickel and iron, known for its excellent magnetic permeability. This high permeability allows permalloy heads to produce highly accurate magnetic fields, which is essential for high-fidelity recording and playback. Permalloy heads offer superior performance in terms of signal fidelity and sensitivity but tend to wear faster than ferrite heads, making them less suitable for high-durability applications.

Sendust is an aluminum alloy, silicon, and iron, developed to combine the advantages of both ferrite and permalloy. Sendust heads provide high magnetic permeability and excellent wear resistance, offering a balance between durability and performance. These heads are particularly valued in high-end audio equipment, where maintaining high fidelity over long periods of time is critical.

Amorphous heads represent another advancement in recording head technology. Made from a non-crystalline metallic glass, these heads offer exceptional magnetic properties and wear resistance. The amorphous structure minimizes grain boundaries, reducing magnetic noise and improving signal quality. Amorphous heads are used in high-fidelity audio equipment, where their superior performance justifies the higher production costs.

Several manufacturers developed their own variations of these materials and used proprietary technologies for head manufacturing. For example, Akai’s GX heads manufactured from single-crystal ferrite, with hardened glass, Sony’s Lasermorphous heads that used lasers to precisely shape and harden the amorphous head surfaces, and others. However, the basic properties described here are true for all these variations.

What Makes a Head?

A head consists of a core of magnetic material arranged into a doughnut shape or toroid, into which a very narrow gap has been let. This gap is filled with a diamagnetic material, such as gold that forces the magnetic flux out of the gap into the magnetic tape medium more than air would and forces the magnetic flux out of the magnetic tape medium into the gap. The flux thus magnetizes the tape or induces current in the coil. A coil of wire wrapped around the core opposite the gap interfaces to the electrical side. The basic head design is fully reversible - a variable magnetic field at the gap will induce an electric current in the coil, and an electric current in the coil will induce a magnetic field at the gap.

The head gap is a small, precisely engineered space in the magnetic core of the head. The size of the gap significantly affects the quality of recording and playback. A narrower gap can record higher frequencies more accurately, leading to better high-frequency response. However, producing such precise gaps requires advanced manufacturing techniques, which can increase the cost of the heads.

The heads contain coils of wire through which an electric current flows. During recording, this current creates a magnetic field in the head gap. The efficiency of this process depends on the number of turns in the coil and the quality of the wire used. High-quality heads use finely wound coils with minimal resistance to ensure a strong and consistent magnetic field.

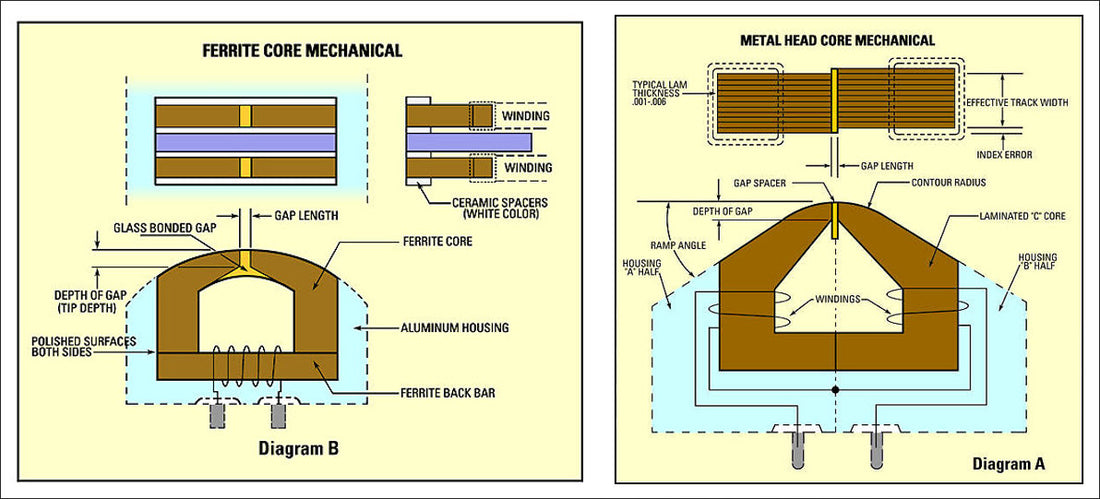

Figure 9 - Metal vs. Ferrite Heads

Erase Heads

Erase heads prepare tapes for new recordings by removing old audio signals. These heads generate a strong, high-frequency magnetic field that disrupts the magnetic alignment of particles on the tape, effectively erasing the stored audio. This ensures that the tape is returned to a neutral state, ready for new recordings without interference from old data.

The erase head typically has a wider gap than the recording and playback heads, allowing it to generate a more powerful magnetic field. This field alternates rapidly, flipping the magnetic orientation of the particles on the tape back and forth. As the tape moves past the erase head, the magnetic particles are randomized, nullifying any previously stored audio information.

The process of erasing a tape involves exposing it to a high-frequency alternating magnetic field. This field causes the magnetic particles on the tape to lose their previous alignment and become randomized. The erase head generates this field by passing an alternating current through a coil of wire, creating a magnetic field that alternates in polarity. The strength and frequency of this field are designed to effectively erase any existing recordings, ensuring the tape is ready for new audio input.

Some tape recorders use a permanent magnet for erasing, but high-quality devices employ an AC erase head for more effective and thorough erasure. The performance of the erase head is vital for preventing old recordings from interfering with new audio, thereby maintaining the integrity of the recording process. The erase head's ability to remove previous recordings without damaging the tape itself is crucial for the tape's longevity and reusability.

Figure 10 - A Unique 2 gap Erase Head

Heads on!

Each material and design choice in recording heads influences the overall performance of magnetic tape systems. From the electromagnetic properties of the head materials to the mechanical configuration of the head gap, these factors are meticulously balanced to optimize sound quality, durability, and cost. This delicate equilibrium highlights the sophisticated engineering behind magnetic recording technology.

Conclusion

The exploration of the basic principles of electromagnetism to the complex interplay of materials science and engineering, each element of magnetic tape recording contributes to the performance and legacy of this transformative technology.

As we continue to delve deeper into the nuances of various tape types and their specific contributions to audio science, we gain a greater appreciation for the pioneers who pushed the boundaries of what was possible. The story of magnetic tape is not just a tale of technological evolution; it is a narrative of human ingenuity and the relentless pursuit of better sound.

This journey through the history and science of magnetic tape recording illuminates the foundational principles and challenges that shaped the development of audio recording technologies. It provides a comprehensive understanding of how innovations in material science and electromagnetic applications drove the evolution of media technology, offering insights into the past and inspiration for future advancements.

In the next article, we will dive deeper into the world of tape bias, the IEC standard, and will begin exploring the various tape formulations in depth.

Credits

- By © User:Colin / Wikimedia Commons, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=30044004

- https://www.sciencefacts.net/magnetic-flux.html

- https://cse.umn.edu/irm/4-domain-theory

- https://idealmagnetsolutions.com/knowledge-base/understanding-coercivity/

- https://www.sciencefacts.net/magnetic-permeability.html

- https://www.electricityforum.com/electromagnetic-induction

- By © Raimond Spekking / CC BY-SA 4.0 (via Wikimedia Commons), CC BY-SA 4.0, https://commons.wikimedia.org/w/index.php?curid=57511173 https://en.wikipedia.org/wiki/Tape_head

- https://www.jrfmagnetics.com/tapeheadintro.html

- By © Raimond Spekking / CC BY-SA 4.0 (via Wikimedia Commons), CC BY-SA 4.0, https://commons.wikimedia.org/w/index.php?curid=57511175

2 comments

Thanks you, for information

Nicely done. Had to read some parts a few times, but it makes sense. Thanks!